ADJUSTMENT AND CONTROL IN OVERVIEW

The following general instructions give you an assistance to belt control. For further questions, we will gladly send you the detailed information material or consult you personally.

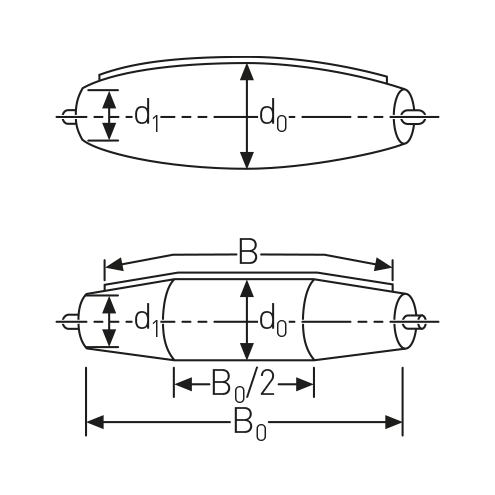

DRUM FORM

| B (m) | B0 (m) | d0 (mm) |

|---|---|---|

| ≤ 0,1 | B+0,01 | ≤ 140 |

| > 0,1-0,2 | B+0,02 | 50-160 |

| > 0,2-0,4 | B+0,03 | 60-200 |

| > 0,4-0,7 | B+0,04 | 80-240 |

| > 0,7-1,2 | B+0,05 | 100-290 |

| > 1,2-1,8 | B+0,06 | 120-330 |

| > 1,8-2,4 | B+0,06 | 140-360 |

| d0 (mm) | d0 - d1 (mm) |

|---|---|

| ≤ 50 | 1,0 |

| 100 | 1,4 |

| 150 | 1,8 |

| 200 | 2,2 |

| 250 | 2,6 |

| 300 | 3,0 |

| 350 | 3,4 |

| 500 | 4,4 |

| > 500 | ≤ 6,0 |

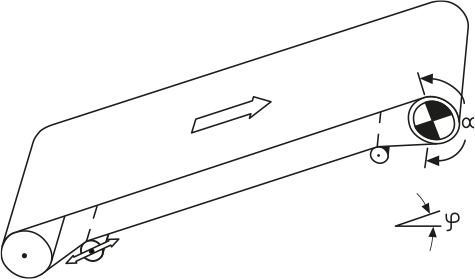

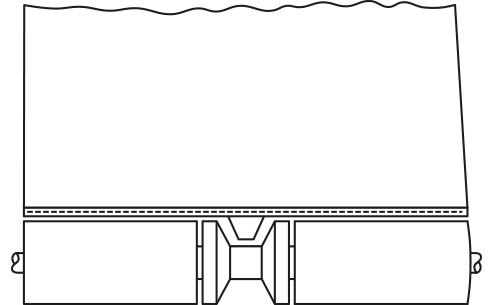

Belt control principle

via a control roller

BELT CONTROL

Belt adjustment

- Align all rollers parallel

- Ensure initial tension and let the belt carry out trial run

- If necessary, correct the belt to run centrically

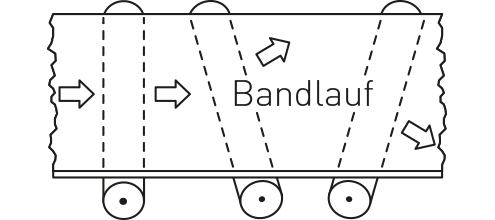

Belt control

For the control roller is applicable: the belt runs out to the side, where it at first has contact with the control roller.

BELT CONTROL BY V-SHAPED GUIDES

From a belt speed of 0.4 m/s, independently mounted V-belt pulleys should be used.

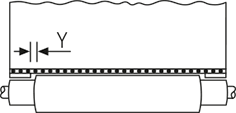

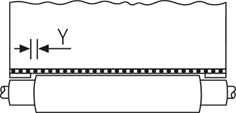

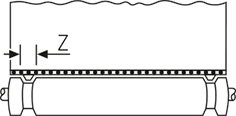

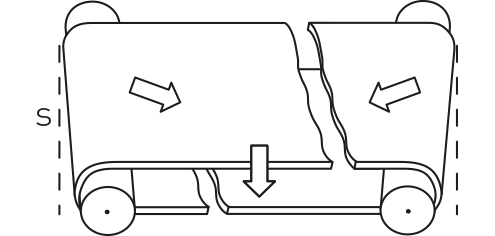

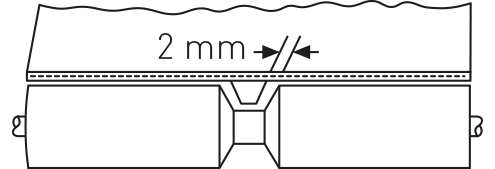

DESIGN OF SLIDING TABLE AND DEFLECTION ROLLERS

| Bandbreite (mm) | X (mm) | Y (mm) | Z (mm) |

|---|---|---|---|

| < 500 | 2 | 4 | b* + 8 |

| 500 - 1000 | 3 | 5 | b* + 10 |

| > 1000 | 4 | 6 | b* + 12 |

b*: see the table “Guides”