Product, service and installation in top quality

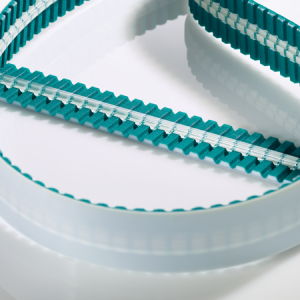

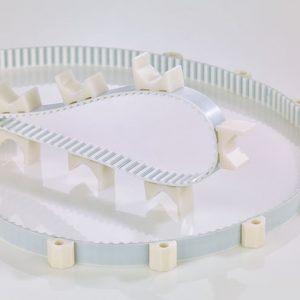

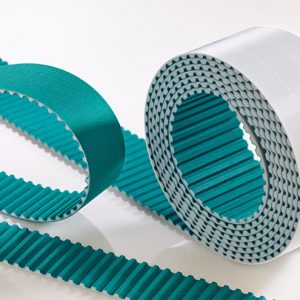

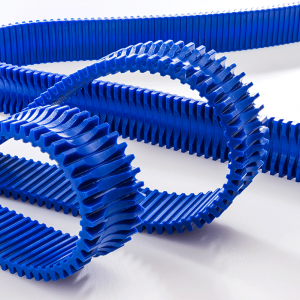

KLUMP timing belts are premium products made of high-quality polyurethane with high-performance tensile cord of steel, stainless steel, kevlar or fieber glass. They are successfully used in synchronous conveyors, for the control of linear movements and in drive systems. We cover a wide range of possible applications, for example in automation and handling technology, in the hygiene and packaging industry as well as in cardboard production. Endless welded timing belts with innovative connection technology, whether welded or mechanically, made of metal and plastic or non-connected flex-belts ensure the greatest possible pulling force depending on the application.

We store all common tooth profiles as rollware and could guarantee a 24-hour service for welded timing belts, as well as on-site installations. We will be pleased to send you our detailed timing belt-

and coating brochure, technical data sheets as well as our sample folder.